Frequently asked questions

See below for answers to frequently asked questions (FAQs). We will update FAQs regularly as the project progresses.

Construction

Three construction precincts will be established along the corridor: the southern, central and northern precinct. Each precinct will accommodate tunnelling operations and surface level construction work to build the lowered motorway and associated urban infrastructure.

The precincts will be purpose built to suit the construction activities taking place in that area. Detailed precinct layouts will be made available as planning is finalised.

Generally, precincts will include:

a tunnel access ramp where the tunnel boring machines (TBM) will enter and exit the tunnels. These ramps are permanent structures that will become the lowered motorway when the tunnelling works are completed. Construction of the ramps involve building large retaining walls and bulk excavation of ground material

an electrical power substation to support tunnel operations such as powering the TBMs and other ancillary equipment like conveyors, lights, fans and pumps

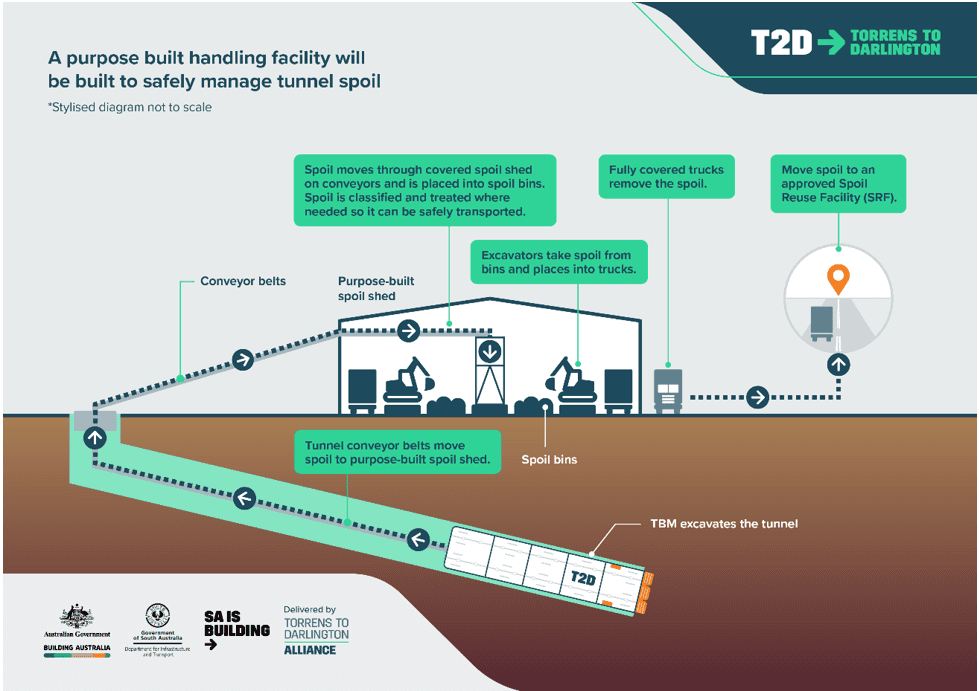

enclosed conveyors to shift the excavated spoil from the tunnels to the spoil shed

an acoustic shed for management of spoil (the excavated rock and soil), storage of machinery and equipment, and to keep noise and dust to a minimum

a water treatment plant to ensure wastewater and run-off from the construction area meets required water quality before disposal

gantry cranes

worker facilities.

Construction hours differ between surface works and tunnelling.

Surface works will normally take place:

Monday to Saturday between 7:00 am and 7:00 pm

Sundays and Public Holidays from 9:00 am to 7:00 pm

While every attempt is made to complete construction work during the day, some night work will be required when traffic volumes are lower and safety can be maintained for motorists, pedestrians and our workers.

Other reasons for night work include:

third party approval limits work to night works

service outage timing determined by the relevant service provider

as agreed with adjacent stakeholders (there may be a preference to carry out the work at night) .

Tunnelling activities will take place 24 hours per day, seven days a week. This includes excavation by tunnel boring machines and tunnel support activities such as spoil handling and loading.

The tunnels will be constructed using tunnel boring machines (TBM), except for short lengths at each end of the tunnels. This is because the roadway would be too shallow to use the TBMs effectively.

For these short lengths, we will construct the tunnels from the surface with a process called cut and cover tunnelling. This construction method involves:

excavating a large open trench using an excavator (cut)

constructing the roof to give a tunnel-like finish (cover).

Spaced concrete beams will form the roof – giving an open tunnel finish.

A large part of the tunnelling operation involves removing ground material from the newly excavated tunnel. The ground material is referred to as spoil. Based on modelling and calculations, tunnelling and excavation will generate about 7.5 million tonnes of spoil to build the open motorway.

Before starting construction, extensive ground investigation works were completed. This was to confirm the geotechnical and groundwater properties along the tunnel alignment. The ground is largely clay-based. This soft ground material requires specialist tunnelling methods.

Once the clay is excavated, trucks move the spoil from the back of the tunnel boring machine (TBM) conveyor to a spoil shed on the surface within the site compound. It is then treated as required. From this shed, trucks with trailers (spoil haulage trucks) move the spoil to approved disposal sites in South Australia.

We install several measures on site to ensure the safe management of spoil:

Before we remove spoil from the site, we test and categorise the spoil so that it is directed to the correct disposal site.

Contaminated materials are handled in line with Construction Environmental Management Plan (CEMP) requirements.

Spoil haulage trucks are fitted with covers to minimise dirt tracking. The covers can be off when there is no spoil in the trailer.

Wheel wash systems installed at each site ensure that truck tyres are clean before leaving.

Options to reuse the spoil are explored where possible.

The tunnels

Construction of the open motorway between two sections of tunnels allows for connectivity to key east and west destinations such as Adelaide CBD, Adelaide Airport, Anzac Highway and other main connector roads.

The design uses a combination of tunnels, lowered and ground-level motorways, as well as overpasses and underpasses to provide the best access to these travel gateways. The design also preserves important cultural and heritage sites, opens up suburbs to new recreational spaces and minimises the extent of property acquisition as much as possible.

Constructing the open motorway between two sections of tunnels connects key east and west destinations. For example, Adelaide CBD, Adelaide Airport, Anzac Highway and other main connector roads.

To provide the best access to these travel gateways, the design uses a combination of:

tunnels

lowered and ground-level motorways

overpasses and underpasses.

The design also:

preserves important cultural and heritage sites

opens up suburbs to new recreational spaces

minimises the extent of property acquisition as much as possible.

The tunnel boring machines used to excavate the tunnels will bore deep underground at around 10 to 25 metres below the surface.

To view the planned location and depth of tunnels in proximity to your property, use the Tunnel tool.

Safety has been at the forefront of the T2D Project design. The tunnels will have a range of features to make sure motorists are safe.

The T2D Project will be a ‘managed motorway’. This means the motorway and the tunnels will have a range of technology-based information, communications and control systems in the motorway, known as intelligent transport systems (ITS).

The systems are designed to actively:

manage traffic flows

improve safety

provide travel time reliability.

We will establish a dedicated traffic management centre to monitor the T2D motorway. It will have a range of tools to make sure traffic moves efficiently along the corridor. This includes measures such as:

coordinated ramp signalling

speed and lane use management

automated incident detection

variable messaging signs (VMS).

If an incident occurs in a tunnel, we will use these systems to coordinate an appropriate response to make sure motorists are safe.

Systems include:

tunnel closure system, so the tunnels can be safely closed when required using boom gates and stop signs to restrict access

automatic incident detection to identify hazards such as stopped vehicles, debris, animals or people

CCTV cameras for constant road monitoring and quick incident management

dynamic variable message signs to provide information to motorists like incident warnings and likely travel time

lane use management system to control speed limits and lane closures for optimised traffic flow and safety

fire detection and suppression systems to activate sprinklers in the event of a fire

radio rebroadcasting, so traffic management centre personnel can broadcast safety messages to motorists in the tunnels via their vehicle’s radio.

Managing impacts

Noise

Tunnel boring machines (TBM) produce some ground-borne noise as they excavate and line the tunnels.

Due to the depth of tunnels and the ground conditions, we do not expect noise from tunnelling to be heard in properties above the tunnels. As TBM advance at about 8–10 metres per day, we typically expect them to pass beneath a property in around 3 days.

There will be some noise from tunnelling activities audible at the tunnel portals during construction. There will be acoustic sheds at each portal to minimise the amount of noise generated by tunnelling activities.

Get the latest TBM locations from our weekly email updates.

Vibrations

We do not expect vibrations from TBM operations to be felt at the surface. It will also be well below the thresholds that could cause structural damage.

Long-term vibration monitors are installed along the construction site boundary. These monitors will check vibration levels in real-time during construction works.

Construction levels and mitigation measures are managed in line with relevant project approvals.

Property condition surveys

We will offer eligible properties in the vicinity of the tunnels and the surface level sites a free property condition survey both:

before work starting

once work is completed.

Learn more about property condition surveys.

This is standard process on major transport projects delivered by the Department for Infrastructure and Transport.

The process gives people a clear understanding of the condition of their property before works occur. It also confirms the condition of the property after the TBM have passed underneath and the tunnel is constructed.

We will do our best to minimise disturbance from our surface construction sites to nearby residents and business. However, some construction activities will generate periods of noise.

We’ll use a range of measures to mitigate noise and vibration impacts, including:

providing advance notice of works to those nearby

monitoring noise and vibration levels during construction

applying at-source measures including temporary and permanent noise walls, noise blankets around mobile work areas and acoustic sheds to enclose tunnelling activities

planning activities to avoid project vehicles and trucks queuing and idling near homes and businesses

checking our equipment, vehicles and machinery are in good working order

limiting truck movements on local roads where possible

locating equipment as far as practical from homes and businesses

implementing respite and relocation measures

administering the Noise Treatment Program at eligible properties.

Due to the nature of the activities taking place, construction work can sometimes generate dust.

To minimise dust leaving the construction sites we will implement various mitigation measures including, but not limited to:

water carts on-site and on adjacent streets to dampen stockpiles, hardstand areas and road surfaces

street sweepers on haulage roads and local roads

polymer binding agent applied to stockpiles

spoil shed enclosing soil deposits

maximising the amount of hardstand area on-site.

Road tunnels can help reduce air pollution by moving vehicles underground and off the roads where people live and work. Road tunnels also reduce travel time and congestion by:

removing the number of traffic lights along the journey

reducing road grades (steepness) and corners.

Within the tunnel environment, vehicle emissions can be controlled and dispersed more effectively. This results in little, if any, change in air quality for people living and working near the tunnel. We will build our tunnels to meet strict air quality standards with state-of-the-art ventilation and tunnel design.

The exit points of tunnels are also known as tunnel portals. During the design process, we use a modelling-based assessment to evaluate potential changes to the air quality surrounding these portals. It is necessary to demonstrate minimal or no change to the surrounding air quality.

During tunnel operation, we measure emission levels with air-quality monitors. This is to confirm that air quality standards are being met. These monitors are installed both inside and outside the tunnels.

Contributors to air pollution include:

residential, commercial and industrial areas

wood heaters

natural events, like bush fires

motor vehicles.

By relocating surface traffic into tunnels, we can also use more space for things that matter most to Adelaide’s communities. For example, open green spaces and trees.

More information

We will provide more information about air quality management after we finalise the design.

In the meantime, our community engagement team is happy to answer any questions you may have.

We are committed to maintaining two lanes of traffic in each direction on South Road during construction. There may be occasional limited closures at night or other off-peak times to facilitate some construction activities. The majority of construction will be undertaken off-site and next to South Road, which will limit impacts to existing traffic.

New Variable Message Signs (VMS) will be installed at key locations to advise motorists of traffic conditions along and around South Road with real-time information.

Use our Surface works map to see what’s happening in your local area and to help you plan ahead. It is updated weekly with the latest work activities.

You can also register for updates.

Some Adelaide Metro bus stops along South Road may be temporarily impacted while work is underway. Advance notice will always be provided ahead of any public transport changes.

Use our Surface works map to see what’s happening in your local area help you plan ahead. It’s updated weekly with the latest work activities including any public transport changes. Please observe bus stop signage and visit www.adelaidemetro.com.au for the latest information on routes and timetables.

Some changes to active transport routes may be required while work is underway. Detour routes will be signposted around our work sites for bike and shared-use paths.

Use our Surface works map to see what’s happening in your local area and help you plan ahead. We update it weekly with the latest work activities, including any changes to active transport routes.

Access to properties will be maintained during construction, unless otherwise agreed with the property owner or tenant.

Where construction activities do affect primary access, we will:

arrange alternative access with the owner or tenant

always provide advance notice.

Wherever possible, residents, deliveries and service vehicles will be permitted access through local road closures.

If you have special access needs and/or mobility issues please contact us to discuss your needs. We will work with you to provide alternative access.

Emergency services are regularly briefed throughout construction. This is to ensure they are up to date with the latest project information and access is always maintained.

We consult with emergency services as part of the planning process ahead of any planned traffic changes.

Resources

The T2D Project will need a broad set of skilled workers across hundreds of different roles during construction. It will support 5,500 jobs per year on average during main construction – creating a skills legacy for South Australia.

The project is committed to providing opportunities for:

local people

Aboriginal workers

apprentices

trainees

jobseekers who are long-term unemployed.

Jobs will include hands-on, supervisory and engineering roles in construction. Most jobs will involve working on-site. However, office-based corporate, drafting and project management roles will also be available.

To register your interest to work on the T2D project, visit our Employment opportunities page.

A property condition survey is an inspection of a building or property to assess and document its general condition. This includes any existing defects.

The survey is offered before substantial construction on the surface or tunnelling begins in your area.

If a pre-construction property condition survey is completed for your property, you will automatically be offered a post-construction property condition survey.

A post-construction property condition survey is a follow-up inspection after construction work is completed. It can be used to determine if there are any changes to the buildings or structures. This offers owners peace of mind during construction work.

Learn more about property condition surveys and who is eligible for one.

The best way to stay up to date on the project is to register for updates.