Tunnel boring machines

Tunnel boring machines (TBM) are very large and complex pieces of machinery that excavate tunnels and can bore through a variety of ground conditions. This allows communities and businesses to continue undisturbed above ground while construction happens below ground.

About the T2D Project TBMs

The TBMs we will use to construct the T2D tunnels will be:

around 100m long with a diameter of around 15m – roughly the height of Thebarton Theatre or Edwardstown Bunnings

operating continuously and progress about 8 - 10m per day

launched and retrieved from purpose-built sites called tunnel portals

manufactured overseas and delivered to Adelaide in modules, it will then take approximately six months to assemble and commission them before they can start tunnelling works.

3 TBMs working

concurrently

There will also be two smaller 4m diameter mini TBMs that will excavate the maintenance cross passages between the main tunnels.

World-leading

manufacturer

The TBMs have been purchased from world-leading manufacturer Herrenknecht.

Operating

continuously

Communities and businesses can continue undisturbed above ground.

More details

The TBMs have been purchased from world-leading manufacturer Herrenknecht. Herrenknecht has also delivered TBMs for projects:

around the world, including the United States, England, China, Singapore, Italy and Qatar

in Australia, such as the Sydney Metro, and the North East Link and West Gate Tunnel projects in Melbourne.

The T2D Project will have three TBMs working concurrently, so that we can construct the Northern and Southern Tunnels at the same time. There will also be two smaller, 4m diameter mini TBMs that will excavate the cross passages between the main tunnels.

These cross passages:

are located every 120m

house equipment which support the day-to-day operations of the tunnels

also form part of the tunnel safety system – allowing access for tunnel and emergency service personnel as needed.

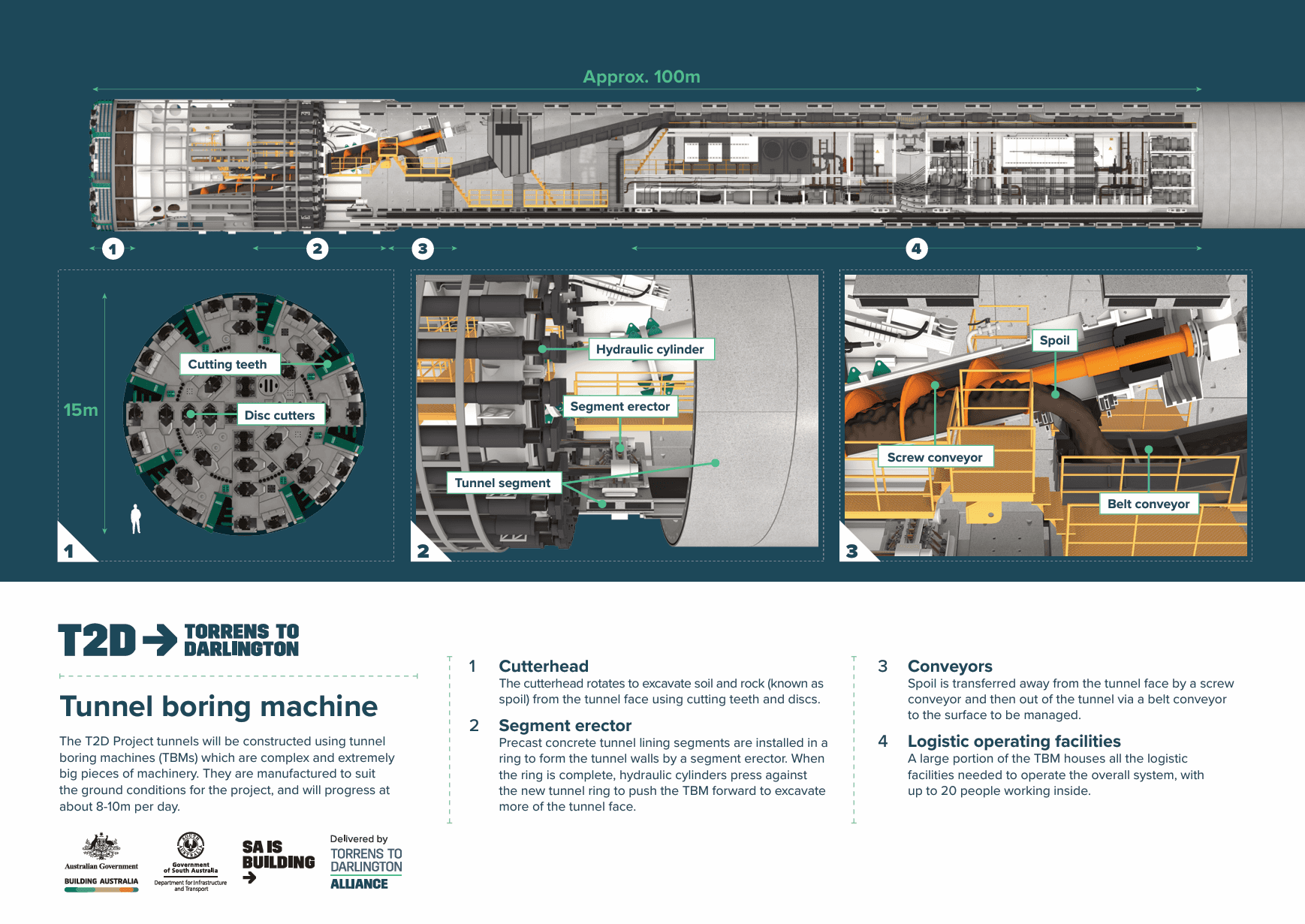

At the front of the TBM, there is a cutterhead with cutter teeth and discs. The cutterhead rotates to excavate soil and rock (known as spoil) from the tunnel face. A series of conveyors move spoil from the front of the TBM to the back, and it is then removed from the tunnel.

A segment erector inside the TBM installs 10 precast concrete tunnel lining segments to form a ring. These rings form the tunnel walls. When each ring is completed, hydraulic cylinders press against the tunnel ring to push the TBM forward and excavate more of the tunnel face.

The rest of the TBM houses logistics facilities needed to operate the overall system. There will be up to 20 specialised people working inside.

Multi-service vehicles move the tunnel lining segments and other materials needed to work in the tunnels into the tunnels. They are 27m long and can be driven from both ends.